Hot rolled steel panels are establishing a more profound impact on the most modern architectural projects which combines industrial elegance with leading edge design. As you may have guessed, hot rolled steel does present some challenges in bringing your contemporary architecture designs to life.

Hot rolled steel panels are establishing a more profound impact on the most modern architectural projects which combines industrial elegance with leading edge design. As you may have guessed, hot rolled steel does present some challenges in bringing your contemporary architecture designs to life.

In your favorite architectural design software, the designs get rave reviews, but when you’re talking about moving from design to real life, the challenges become more apparent, especially in terms of weight. Hot rolled steel panels, even when only used for, or attached to walls, are very heavy in weight causing undue stress and strain on the structure. Not so bad for a new design, because the structure can be built from scratch to accommodate the weight of the hot rolled steel but for the remodel or retro-fit projects, the sheer weight of hot rolled steel can be hugely problematic.

To mitigate the challenges of hot rolled steel contemporary architects are reaching out to companies, like “Sing Core” to help redesign the structure of the hot rolled steel panels without compromising the structural integrity of the hot rolled steel while reducing the weight significantly.

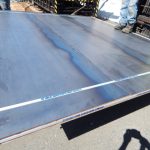

The concept is based on inventor Peter Sing’s patented reinforced vertical grain torsion box core which weighs about ten percent of solid wood core yet is surprisingly many times stronger. In fact, in independent university testing trials, Sing Core tested at 660+ PSI, which is stronger than steel pound-for-pound. If that’s not enough, the inventor’s web site features many photographic representation of panels built with his patented core suspended amidst long unsupported spans under stress with little or no deflection, like this photo of two people standing on a 1” galvanized steel panel 20 ft. long:

“breaks the laws of physics”

Sing’s core solution is gaining popularity among the most high end architectural and design projects around the world to quote one engineer, “almost breaks the laws of physics as we know them.”

This makes the production process look much different as huge panels of enormous size featuring heavy exterior materials can be carried around the job site by hand instead of having to use heavy equipment to transport and install the lightweight panels with Sing Core inside.

Sing Core is taking a more proactive approach in making what some have referred to as, “the best metal panels,” which is why you are seeing these Eco-friendly metal panels specified in more and more architectural designs these days, as they are made expending less energy, handmade, cold-pressed which is very unlike any other approach to other steel fabrication processes. Formaldehyde-free adhesive are used and Sing’s panels can support steel of 16 gauge or more.

Sing’s steel architectural doors are also high precision, more high precision than welded steel doors due to the +/- .006 inch tolerance of Sing Core, resulting in the flattest and straightest warp-free architectural steel door that can be covered by Sing’s 50-year guarantee.

Besides wall panels, the far more popular variety of hot rolled steel featuring Sing Core inside will be found in large hot rolled steel doors, most predominantly hot rolled steel doors, for the same reasons both weight and strength which are concerns when working with architectural door designs. By using Sing’s hot rolled steel door slabs, contractors can use lighter weight framing and hardware.

Yes, Sing is so confident in his hybrid high/low tech solution that he guarantees his professional hot rolled steel for 50 years without hesitation. This is probably the reason high end clientele is seeking solutions, like those being offered by Sing Core. Why? Because large doors (especially large wooden doors) are prone to warp, and are normally excluded by any warranty which might accompany the other doors in the project. Sing’s doors are guaranteed for 50 years not to warp, bend, twist, or otherwise fail for 50 years, including a full 50-year structure warranty.

That’s why you’re seeing such an increase in the demand for Sing Core in architectural specifications as big metal doors, steel double doors, industrial steel doors, and in other doors, such as a commercial metal door, which can now possess its own 50-year guarantee.

Besides double steel doors and hot rolled steel swing doors, you will see Sing’s hot rolled steel flooring, hot rolled steel counter tops, hot rolled steel wall panels and room dividers, increasingly specified in architectural designs.

So, whether you’re looking for hot rolled steel pivot doors or hot rolled steel sliding doors, Sing Core is the only way to build a hot rolled steel door that can be guaranteed for 50 years.