Contemporary Architecture Design recommends the high performance lightweight advantage of patented Reinforced Structural Insulated Panels invented, provided and manufactured by Sing Core in the Northwestern United States of America.

How lightweight are these RSIPS?

These patented RSIPs are only 20% the weight of solid wood.

Weighing-in at only ½ to 2 lbs. per square foot.

How is it possible?

These patented RSIPs are the best of high-quality wood craftsmanship and aerospace technology resulting in a composite panel that is not only lightweight but stronger than steel pound-for-pound.

Torsion box hybrid

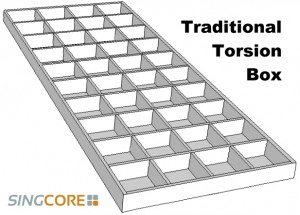

Torsion box design in woodworking is basically a number of wooden boxes assembled together to make up the core material sandwiched between two sheets of wood. This is a labor-intensive process for craftsmen, but does produce a lighter-than-solid-wood product that has increased strength due to the torsion box interior.

Torsion box design in woodworking is basically a number of wooden boxes assembled together to make up the core material sandwiched between two sheets of wood. This is a labor-intensive process for craftsmen, but does produce a lighter-than-solid-wood product that has increased strength due to the torsion box interior.

Craftsmen have been using torsion box for centuries, but it takes a skilled craftsman hours if not days to create a table… Sing Core provides craftsmen with the torsion box structure pre-built. Doing so allows you to make 50 times more tables or 100 or more Sing Torsion Box 2 in x 12 inch x 8 planks in a single day. Wood products made of patented Sing Torsion Box lumber, panels, posts or beams can be easily mass produced in a small work shop without adding any heavy wood working machines. The labor-saving and high-quality will make it possible to bring the furniture making jobs back home, creating jobs and improving local economies while reducing the impact of imported furniture.

Inventor Peter Sing has taken torsion box technology to the next level, making massive improvements to the primitive, yet effective, torsion box design.

The first improvement on the traditional torsion box design was so simple that it was merely, “a gift,” as Sing explains. Torsion box grids have always been an effective way to produce a large wooden surface, while retaining some integrity of strength and resulting in a lighter weight end product. “But,” says Sing, “the wood material used to construct the torsion boxes always used horizontal grain.” By reorienting the grain to be vertical, the resulting torsion box became 10 times stronger than the horizontal grain original designs, but he wasn’t done, yet…

Sing Improvement # 2: Fill the void.

The next step was to fill the void with a stable, yet lightweight, material. Recycled foam was the answer. By filling the vacant space in each cavity of the torsion box, edge to edge greatly increased the strength of the torsion box, as well as adding insulation and sound deadening properties, without adding much noticeable weight increase.

Sing Improvement # 3: Fuse the structure.

The final step in Sing’s revolution in torsion box design was to develop a method to bond all the necessary components together resulting in a nearly indestructible, yet solid, lightweight structure. Experimentation led to discovering superior bonding agents for superior adhesion that will not breakdown due to stress on the structure or over time… and this was achieved without the use of formaldehyde or toxic chemicals.

The result is a natural torsion box design combined with recycled materials that could be used as a substrate for nearly any building material, making Sing Torsion Box the composite material of the future.Sing Core is also Eco-friendly, “True green,” Sing calls it because it is all manufactured naturally, with little energy consumption, uses recycled materials with little or no waste. It also reduces the greenhouse effect in fuel expended in the delivery of the material due to being so lightweight. Manpower reduction is also an effective savings due to its lightweight characteristics.

The result is a natural torsion box design combined with recycled materials that could be used as a substrate for nearly any building material, making Sing Torsion Box the composite material of the future.Sing Core is also Eco-friendly, “True green,” Sing calls it because it is all manufactured naturally, with little energy consumption, uses recycled materials with little or no waste. It also reduces the greenhouse effect in fuel expended in the delivery of the material due to being so lightweight. Manpower reduction is also an effective savings due to its lightweight characteristics.

Sing Core is proudly manufactured in the USA in McCleary, Washington, and due to its lightweight attributes can be shipped to any location on Earth at a fraction of the cost of other, traditional solid building materials while maintaining strength over long spans, much stronger than any other natural materials.

Peter Sing was awarded a patent on his improvements to the traditional torsion box technology and eagerly desires to share his invention with the masses in an effort to, “make the world a better place.”